Battery manufacturing is a complex and highly specialized process that plays a pivotal role in powering our modern world. It begins with the production of raw materials, such as lithium, cobalt, and nickel, which are mined and refined to create the essential components of the battery cells. With a reliable supplier network established, Pulsar Industries can quickly assess product costs and work toward developing working prototypes using state-of-the-art production technologies.

Battery Industries

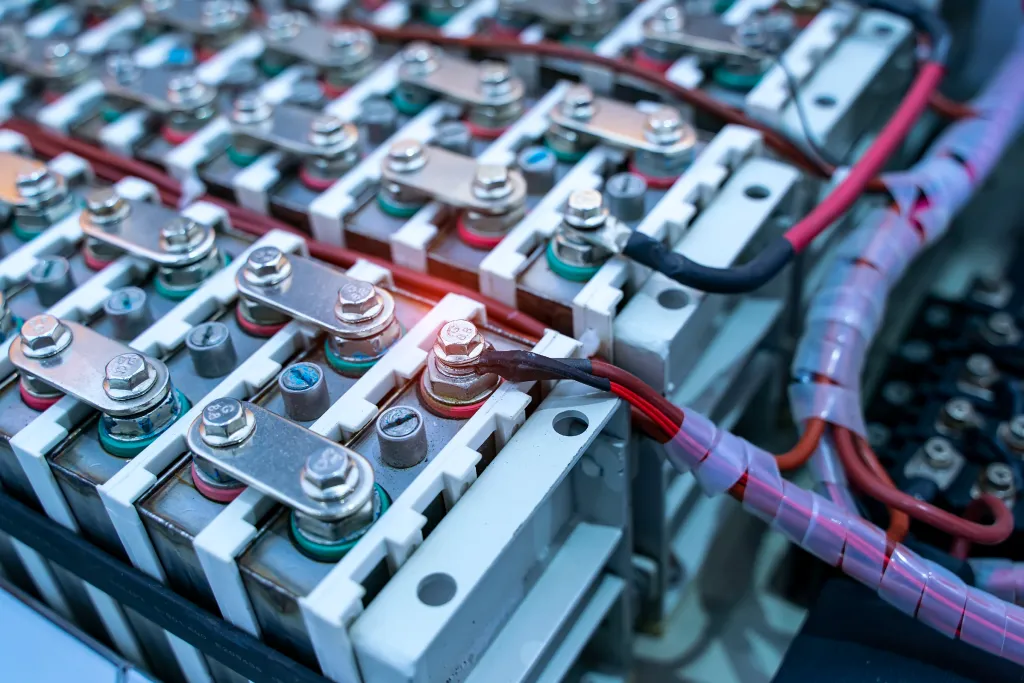

Battery manufacturing is a complex and highly specialized process that plays a pivotal role in powering our modern world. It begins with the production of raw materials, such as lithium, cobalt, and nickel, which are mined and refined to create the essential components of batteries. These materials are then processed and combined to form the battery’s electrodes and electrolyte. The electrodes are typically made of a mixture of materials, including lithium-ion and graphite, while the electrolyte serves as the conductive medium that allows the flow of ions between the electrodes. Precise control of the composition and quality of these components is critical to the performance and safety of the battery.

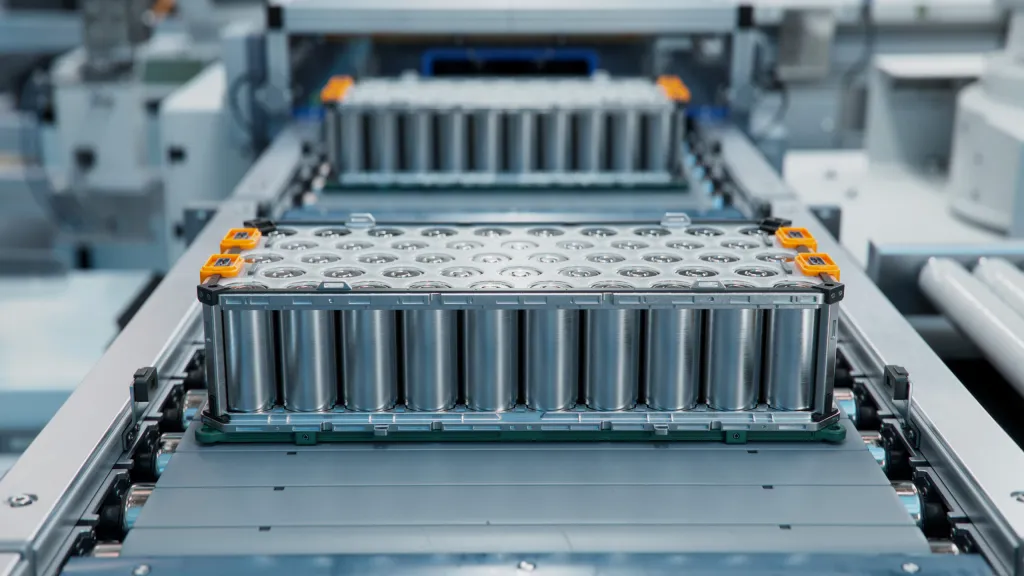

Once the core components are ready, they are assembled into various battery cell formats, including cylindrical, prismatic, and pouch cells, depending on the application. Advanced automation and quality control measures are employed to ensure consistency and reliability in the manufacturing process. After assembly, the cells undergo rigorous testing to verify their performance and safety characteristics. These tests include assessments of capacity, voltage, temperature stability, and cycle life. Finally, the cells are integrated into battery packs, which are used in various applications, from electric vehicles to portable electronics and renewable energy storage systems. Battery manufacturing continues to evolve with ongoing research and development efforts focused on improving energy density, reducing costs, and enhancing sustainability to meet the growing demand for clean and portable power solutions. This is where Pulsar Industries’ expertise comes in, and together, we can help you achieve it.

Once the core components are ready, they are assembled into various battery cell formats, including cylindrical, prismatic, and pouch cells, depending on the application. Advanced automation and quality control measures are employed to ensure consistency and reliability in the manufacturing process. After assembly, the cells undergo rigorous testing to verify their performance and safety characteristics. These tests include assessments of capacity, voltage, temperature stability, and cycle life. Finally, the cells are integrated into battery packs, which are used in various applications, from electric vehicles to portable electronics and renewable energy storage systems. Battery manufacturing continues to evolve with ongoing research and development efforts focused on improving energy density, reducing cost, and enhancing sustainability to meet the growing demand for clean and portable power solutions is Pulsar Industries expertise and together we can help you achieve it.

Solution

Battery Manufacturing Solution

Battery manufacturing is a complex and highly specialized process that plays a pivotal role in powering our modern world. It begins with the production of raw materials, such as lithium, cobalt, and nickel, which are mined and refined to create the essential components of the battery cells. Having a reliable supplier network established, Pulsar Industries can quickly assess the product costs and work towards working prototypes using state-of-the-art production technologies.